Following are the equipment in this laboratory used for various purposes

Pneumatic Servo System to simulate and study all types of Hydraulic and Pneumatic valves for flow control, direction control and pressure control.

Following are the equipment in this laboratory used for various purposes

Following are the equipment in this laboratory used for various purposes

Refrigeration and Air Conditioning (RAC) lab is an educational and research facility for hands-on learning and experimentation with cooling and environmental control systems, offering practical experience with refrigeration cycles, psychrometric processes, and performance evaluation of equipment like vapor compression systems, heat pumps, and air conditioners. This lab is equipped with various test rigs and instruments to demonstrate principles, analyze system performance, and support student projects for academic programs in engineering.

Purpose and Objectives

Hands-on Learning:

Provides practical experience with the working principles of refrigeration and air conditioning systems. Thermodynamic Analysis:

Facilitates the study of refrigeration cycles and psychrometric processes (properties of moist air).

Performance Evaluation:

Allows for the evaluation of the performance of different systems and components.

Research and Projects:

Supports undergraduate and postgraduate research projects, as well as career development in HVAC (Heating, Ventilation, and Air Conditioning).

Key Equipment and Facilities

Refrigeration Test Rigs:

Units for studying various cycles, including vapor compression, vapor absorption refrigeration.

Air Conditioning Trainer:

System for demonstrating air-conditioning processes, such as duct-type units.

Heat Pump:

Demonstration of heat pump

Specialized Equipment:

Ice plant test rig, domestic refrigerator setup

Instrumentation:

Instruments for measuring temperature, pressure, humidity, and air velocity, often used with psychrometric charts.

Following are the equipment in this laboratory used for various purposes

Following are the equipment in this laboratory used for various purposes

{slider= Material Testing laboratory}

CAD/CAM caters to the requirements of development of basic conceptual design for an engineering component then carrying out stress/strain analysis of the conceptual model built by using sophisticated design software like

Following are the equipment in this laboratory used for various purposes

This workshop caters to the requirement for all the students from textile, electronics and mechanical department. Workshop is equipped with following machinery required to carry out basic mechanical engineering operations like turning, welding, milling, drilling, shaping, etc.

Machines available in this workshop:

Following are the equipment in this laboratory used for various purposes

This lab is equipped with various testing rigs for various types of I.C engines

All the engine test rigs are having facility to check the performance under varying load conditions by rope brake dynamotor or hydraulic dynamometer. Duel fuel type generator set developing 2.5 Kilo Watt power with testing panel backs up the lab.

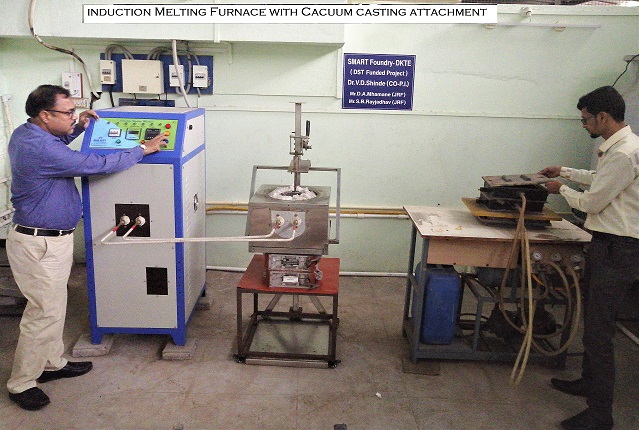

SMART Foundry 2020 project under TSDP of DST

Ten research institute including public and private engineering collages as well as govt. R&D organizations have come together to reinvent metal casting process for education and entrepreneurship by leveraging the latest techniques in 3D Scanning, CAD Simulation, 3D printing and tabletop metal casting technologies.

There is a need to accelerate manufacturing in developing countries like India, to provide employment for millions of young people and contribute to economic development, but this needs to be achieved with minimal adverse impact on the environment. Smart manufacturing allows wider distribution of related activities, creating employment opportunities closer to the end‐users based on their need, and reducing wastage of production resources as well as logistics. The enabling technologies, which are all broadly related to information technology, can be used to reinvent the manufacturing processes, especially metal casting, to make it more sustainable. The SMART Foundry system being developed by a collaborative team of researchers across India, is expected to get young people interested in manufacturing, who can set up small scale businesses, becoming job creators instead of job seekers.

The SMART Foundry 2020 team consists of 12 eminent scientists from 10 high ranking institutes. CSIR‐NIIST, Trivandrum; CSIR‐CMERI, Durgapur; VNIT, Nagpur; Jadavpur University, Kolkata; IIT Bombay, Mumbai; CHARUSAT, Anand; COE, Pune and Dr. Vasudev Shinde, DKTE TEI, Ichalkaranji. The total investment amount for the project is 83.694 lakhs.

MODERNIZATION OF INTERNAL COMBUSTION ENGINES LAB is sanctioned under the Modernization and Removal of Obsolescence (MODROB) scheme with Rs.1559608/- (Fifteen Lakh Fifty-nine Thousand Six Hundred Eight Only).

The undergraduate, postgraduate, and Doctoral research work in the field of fuels and engines need to develop the experimental set-ups which require not only time but a huge expenditure in the development of engine set-ups as per their requirement. It consists of a computerized engine set-up for both Diesel and Petrol fuels with variable compression ratios. This setup allows us to test the engine performance, particularly with the use of alternative fuels and blends as the substitute for Diesel and Petrol fuels. The results can be obtained quickly in a form ready to use in the research work.

AICTE-IDEA (Idea Development, Evaluation & Application) Lab scheme was launched by AICTE on January 1, 2021 to establish infrastructure supporting new-age learning, in its institutions. This is aimed at encouraging students to apply Science, Technology, Engineering, and Mathematics (STEM) fundamentals on ideas- towards enhanced hands-on experience, learning by doing, and even product visualization.

Major Equipment's in AICTE IDEA Lab

Major Equipment's

DEWESoft 7.0.4

The Mechanical Engineering Computer Laboratory is a state-of-the-art facility designed to support students and researchers in advanced computational and design tasks. The lab is well-equipped with modern infrastructure and software to enhance teaching, learning, and research activities.

Key Features:

Objectives of the Lab:

To provide hands-on training in modern design and analysis tools.

To support academic projects, industrial consultancy, and research activities.

To encourage innovation and creativity in product design and development.

To bridge the gap between theoretical knowledge and industrial applications.

This facility plays a vital role in enhancing the technical skills of students, preparing them to meet the challenges of modern mechanical engineering industries.